Inspired by his father’s discussions about the expense and ecological impact of traditional burials, John began crafting simple wooden caskets in 1982. However, it was the experience of building his first urn for his late father in 1990 that truly ignited his passion for creating respectful and sustainable funeral options.

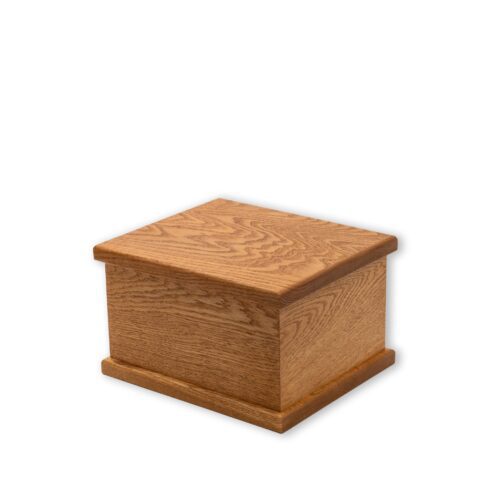

Today, based in Sheboygan, Wisconsin, John produces a range of pure and beautifully detailed cremation urns that are built with heirloom quality and craftsmanship. With a commitment to using locally sourced materials whenever possible, John’s products offer families a meaningful way to honor their loved ones while minimizing waste and financial burden.

John Church

Founder / Craftsman

A Note From John Himself

I vividly recall a heartfelt conversation with my father back in 1982 about crafting simple wooden caskets. His concern was rooted in the high costs associated with traditional funerals, an expense that can be quite substantial. It’s a financial consideration that many of us need to thoughtfully include in our life’s financial planning.

My father, who spent most of his life as a farmer, deeply understood the importance of preserving our precious earth. He was particularly mindful of the materials returned to the soil during traditional burials – such as cement, steel, and formaldehyde. His lifelong connection with nature made him acutely aware of how crucial it is to protect our environment whenever we can.

My brother and I crafted our first urn in 1990, following the loss of our beloved father. The urn was made from a majestic black walnut tree that grew on our family farm, a tree we had sawn with Dad and my brothers using Dad’s sawmill. The lumber was air-dried in the machine shed, not initially intended for an urn. However, after Dad’s departure, we felt it fitting to use a part of this noble tree as his final resting place. We still hold onto some parts of the land that my parents acquired back in 1963 – the very land that nurtured this tree. Today, trees continue to grow there; the creek continues its gentle flow; crops continue to flourish just as Dad always believed they would.

The memory of crafting that first urn has stayed with me over the years. In the time that followed, I had the honor of creating several more urns and a few caskets for loved ones. I understood, just like my father did, that many people wish to leave this world without imposing unnecessary waste or financial strain on their families through traditional casket funerals. However, it’s equally important to ensure that their farewell is dignified, beautiful, and personal – a true celebration of their life and legacy.

In 2016, my beloved wife Kelly and I embarked on a new journey, relocating to the charming town of Sheboygan, Wisconsin. Inspired by heartfelt conversations with my father, we resolved to invest our time and resources into transforming these dialogues into tangible reality.

Today, I am proud to offer an array of cremation urn options that embody purity and simplicity while showcasing intricate beauty. Each piece is crafted with the kind of quality and craftsmanship that ensures it can be passed down as a cherished heirloom. My commitment is to always create products in America – each one meticulously hand-crafted right here in Sheboygan, Wisconsin using Midwest-sourced lumber and domestically sourced materials whenever possible. This is my tribute to our homeland’s rich heritage of craftsmanship.

– John Church